Vinyl click floors or LVT form an excellent product that is much more useful than those based on wood or laminates. How in this light looks floor with Titanium Nano Layer.

Firstly we must remember that it is not an indestructible product. The most common complaint by vinyl users is that they are prone to scratching. That is why some manufacturers have recently focused on trying to reduce this problem. This led to the creation of the patented Titanium Nano lacquer layer, available in the Amaron and Liberal collections. Importantly, the lacquer causes no visual changes to the panel appearance. The panels remain pleasant to the touch, warm and matte. They still resemble natural wood and their properties are closer to those of ceramic tiles.

A new floor in a house or apartment can completely change a room.

A new floor in a house or apartment can completely change a room.

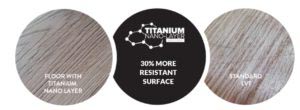

Their comfort is confirmed not only by the quality, but also by the durability. In choosing floor panels we usually take into account the abrasion classes (for laminated panels) or utility (for vinyl panels). If a new floor is to make a good impression for many years, it must be very resistant. Resistant not only to moisture and impacts, but also to scratches. Scratches are the most frequently reported problem by people who use panels. Some panels on the market already have an additional lacquer layer for protection – such as Titanium Nano Layer, which increases the scratch resistance by up to 30%.

What is it about abrasion and usability classes?

For both laminate and vinyl panels, there are many tests that can be carried out to determine their durability. For laminated panels we use the popular abrasion class (AC), while for vinyl panels we use the utility class. The latter tells us more about the durability of the product, because it is a much broader category.

The utility class determines whether a specific vinyl floor is suitable for use in residential, commercial or even industrial buildings.

There are three classification classes used to define the specific properties of a vinyl floor:

- Firstly Class 2 – residential buildings, divided into class 21 for low traffic, 22 for normal traffic, and 23 for high exposure to traffic.

- Secondly Class 3 – commercial buildings, divided into classes 31, 32, and 33, depending on the volume of traffic.

- Class 4 – industrial buildings, similarly divided, but very hard to achieve in real conditions.

This classification allows the intuitive identification of the flooring type required in a specific kind of room. For example, for an apartment with high intense use, we should look for vinyl panels of class 23.

To define the utility class, we need to perform as many as 11 tests, and the abrasion class (AS) is just one of them.

The utility class is more objective – in certain applications the floor is impacted by more factors than just abrasion. These 11 tests include the large ball resistance test, castor chair test, stain resistance test, lock strength test, and dimensional stability over temperature test.

However, if we were to compare these classes then the Amaron vinyl panels, for example, pass the tests for AC5 laminated panels, which is the highest resistance class.

Structure of scratch resistant vinyl panels- Titanium Nano Layer

In order to understand this problem, it is necessary to understand the structure of the vinyl panel. When we talk about rigid panels (SPC), we can distinguish several layers. The best vinyl panels have a surface layer and an outer lacquer, when viewed from above. Thanks to this design, the print remains strong and durable. The protective surface layer significantly reduces the susceptibility of the panels to scratches. This is especially important in homes with small children and pets. Vinyl panels with poorer ratings lack printing secured by a surface layer, which significantly reduces their abrasion resistance. Products without this layer are not very durable, and even after just a few months they look unsightly.

Such a panel is certainly quite scratch resistant.

But there is already a solution on the market that increases the scratch resistance of vinyl panels by as much as 30%. This is an additional layer of lacquer, which creates an invisible coating that protects the panel against micro-damage. One example is the Titanium Nano Layer developed by Decora. It improves the scratch resistance of the panel by as much as 30%.

For several years now, a car paint coating protection has been available at professional paintwork shops. For several thousand PLN we can protect the basic paint coating. Such a service is most often performed when we have a new car that has just left the car showroom. The original paintwork is coated with nanoparticles. This is intended for demanding customers who wish to enjoy the beautiful appearance of their car for years. We may say that Titanium Nano Layer is inspired by these exclusive automotive solutions. Titanium Nano Layer protects the panels and prevents the micro scratches that appear during normal use. The Titanium Nano Layer coating is available in the top Arbiton collections: Amaron and Liberal.

The technology used in these collections gives us one of the most durable and scratch resistant vinyl panels on the market.

Therefore, they are resistant to sand, earth and even mud, because they are also completely waterproof. This, in turn, means that we can easily install them in a kitchen, dining room or even bathroom. Thanks to this technology, we can create a uniform floor measuring some 200 square metres without the need for additional expansion joints. The mineral core in combination with the Titanium Nano layer makes Arbiton floors a guarantee of beauty for many years to come. Although there are no panels on the market that are 100% scratch-resistant, there are panels that almost eliminate the problem.