How to identify the AC class of vinyl tiles?

Technical parameters play an increasing role when it comes to deciding on materials for the home. In the case of vinyl tiles, it is vital to choose proven products with good parameters. Only this can guarantee a beautiful, long-lasting floor serving you for many years to come. Consumers are becoming more familiar with the technical parameters used for floor tiles. Who has not heard of the “AC” abbreviation, commonly understood as the level of tile resistance? What does it really stand for and can it be found on vinyl tiles?

The “AC” abbreviation is always followed by a number: 3, 4 or 5 describes the so-called abrasion class. It is one of the essential parameters determining the durability of laminate tiles. The durability of the laminate surface is in this case measured with the Taber test (EN15468:2013). The test requires placing a circular tile sample on a moving platform that rotates around its own axis. Then, abrasive disks are lowered to the surface of the sample and pressed with appropriate force. After some time, circles appear on the sample. They indicate the material wear after a specific number of cycles. The more rotations the tile withstands, the higher the AC class it receives.

The abrasion class is sometimes misunderstood as an objective rate of the durability of the underlay.

A consumer that has chosen an AC5 floor with high abrasion resistance thinks that they have bought a product for many years. Nothing is further from the truth. The AC class is one of many parameters determining the durability of a floor. It may happen that an AC5 floor in a restaurant will look horrible after 12 months of use.

Is the floor in the picture above an example of a damaged abrasive surface? No, it is not. That floor was damaged because of frequent washing that led to water absorption at the junction of the tiles and to swelling of the core. The abrasion class does not refer to this type of damage at all.

The AC parameter does not describe the durability of vinyl tiles. For vinyl tiles another, much more accurate scale is used – the utility class. This parameter defines whether a specific vinyl floor will be suitable for use in residential, commercial, or even industrial buildings.

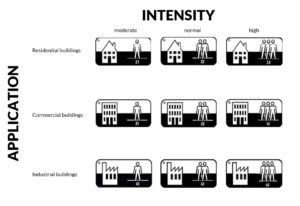

There are three classification classes used to define specific properties of the floor:

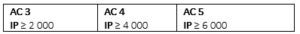

- Class 2 – used for residential buildings; it is divided into class 21 for low traffic, 22 for normal traffic, and 23 for high exposure to traffic.

- Class 3 – a commercial class divided into classes 31, 32, and 33, depending on the volume of traffic.

- Class 4 – class for industrial buildings, similarly divided, but very hard to achieve in real conditions.

How do utility classes transfer to the application of a specific floor in real conditions?

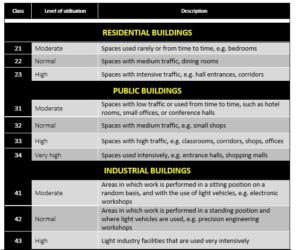

According to the EN 16511 standard, which is a guideline for laying vinyl tiles (multi-layered, semi-rigid) in a floating system, the utility classes can be matched with specific applications:

This classification allows for an intuitive identification of a floor needed in a specific room.

The utility class is a parameter that is much more complex and challenging. To define the utility class, you need to perform as many as 11 tests and the abrasion class (AS) is just one of them.

The utility class is more objective – in different applications, the floor is impacted by more factors than just abrasion. These 11 tests include, among others, the large ball resistance test, castor chair test, stain resistance test, lock strength test, and dimensional stability over temperature test.

The following classification can be used to estimate the abrasion test results for a specific utility class.

The number of cycles of the abrasion test/Taber test and the right AC category are as follows:

In practice, the test is performed until the top surface is worn out.

Of course, you need to remember that the structure of laminate tiles is different than that of vinyl tiles, therefore standards are adjusted to the material characteristics.

Arbiton and Afirmax floors have a very high resistance to abrasion, and they can be classified under class 33.

Despite being adjusted to the standard, vinyl floors from the Amaron collection can withstand even 7000 cycles – that is AC 5 – and be classified under class 33. Results of the wear resistance test for the Liberal and Afirmax collections classify them under class 33; however, when considering the remaining 10 tests, these floors represent utility class 32. Once again, it is necessary to underline that utility classes are more accurate parameters of the floor durability.

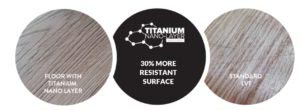

It should be noted that abrasion resistance and scratching resistance are not equivalent. They are two different parameters. You should choose vinyl tiles with a special protective coating that increases the scratching resistance of the floor. Arbiton introduced this solution in the Amaron and Liberal collections. The Titanium Nano Layer is a unique layer of special varnish that improves the scratching resistance of panels by as much as 30%.

In practice, tiles with the Titanium Nano coating are more resistant to scratches being made a result of leaving some sand or grit on the floor or moving furniture.

Summing up, the abrasion class is definitely not enough to identify the durability of the floor. To learn whether the floor is robust and will last for many years, you must check all its technical parameters. While choosing vinyl tiles, look for those with a high utility class (23 or 33). It is the only way to enjoy a perfect floor for many years to come.