Vinyl panels are becoming more and more popular. They are a perfect solution for underfloor heating, they are durable, waterproof and, unlike ordinary laminate panels, they are quiet. There are various types of vinyl panels that differ in the method of installation and the technologies used. The latest category that is taking the market by storm are SPC panels. However, their popularity caused that many products that do not meet quality standards and consumer expectations hit the market. How to choose a good SPC panel? What to pay special attention to?

What is vinyl flooring?

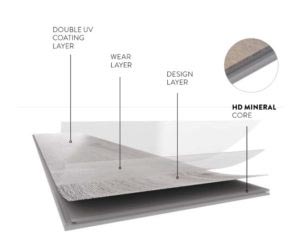

Customarily, “vinyl” floors are products made of plastics or their combinations with other materials. They have a multi-layer structure and their most important common feature is water resistance.

Vinyl panels are a broad category of products. The newest and currently the most often chosen are SPC panels. They are vinyl panels with a rigid, extremely durable core that conducts heat perfectly. The name SPC means solid polymer core. In the West, the name FULL RIGID is also used to describe them.

Vinyl panels are a broad category of products. The newest and currently the most often chosen are SPC panels. They are vinyl panels with a rigid, extremely durable core that conducts heat perfectly. The name SPC means solid polymer core. In the West, the name FULL RIGID is also used to describe them.

SPC panels have all the advantages of the first generation LVT PVC panels, while eliminating their main drawback. Good SPC panels are dimensionally stable – they do not change dimensions under the influence of temperature changes. An example of a hard core used in SPC panels is HD Mineral Core. It is a mineral core made of natural rock minerals and modern polymers. It provides exceptional impact resistance and conducts heat well. Panels with a mineral core (HD Mineral Core) are beautiful as wood and practical as ceramic tiles.

They are indistinguishable from real wood in appearance, and in use they resemble tiles. Dimensional stability allows you to lay up to 200 m2 of panels without the need for additional expansion joints. Because of this there is no need to use thresholds or profiles in the door. Panels of this type have gained many supporters, and the users, apart from appearance, praise the ease of cleaning and nice structure among the practical aspects.

SPC panels – look at them carefully.

On the wave of popularity of SPC panels, more and more products whose quality is questionable appear on the market. How to distinguish a solid SPC panel from a poor fake? There are several features that will allow you to quickly assess the quality of SPC panels.

A matter of great importance – a good SPC panel must weigh.

A good SPC panel should be of high density. Therefore, these panels are quite heavy. High density is a guarantee of durability of the product. Thus, the lower the weight, the lower the density of panels. Unfortunately, lightweight SPC panels can easily be damaged and do not retain their original size during temperature changes (low dimensional stability). So if you want to perform the first quick quality test of SPC panels, compare their weight.

Lightweight, rigid, low-density panels are a type of panels known mainly from American interior design programs and some DIY stores. In the case of EPC – extruded polymer core – the core is a mixture of PVC and chalk that was foamed. It is this technology that makes the panels lightweight. Unfortunately, this affects their durability. The air-filled core is easy to damage. This solution is also much less effective when using these panels for underfloor heating. Such panels are also not as resistant to the fall of heavy objects as panels with a mineral core.

Big deal – a good SPC panel can’t be ultra-thin

The thinnest vinyl planks are 2-2.5 mm. These are panels intended for gluing or self-adhesive. They require a perfectly even floor. Most often, a new screed is made, which is then sanded, primed and prepared especially for gluing vinyl panels. This work requires specialized tools and considerable experience. The panels are glued by specialized assembly teams, and such floor is most often installed in large public buildings.

The thinnest vinyl planks are 2-2.5 mm. These are panels intended for gluing or self-adhesive. They require a perfectly even floor. Most often, a new screed is made, which is then sanded, primed and prepared especially for gluing vinyl panels. This work requires specialized tools and considerable experience. The panels are glued by specialized assembly teams, and such floor is most often installed in large public buildings.

Click vinyl panels must be thicker. This is due to the technology of their production and the need to mill the locking grooves. Modern locking grooves are extremely precise, and cutting them out is the most complicated element of the production process. However, the individual elements of the tongue must have a certain strength, so the click panels should not be thinner than 4mm. And although the pressure of lower prices forces the use of less material, i.e. slimming the panels, the offer of reputable companies does not include panels below 4 mm thick. This is a strong recommendation!

Too thin a panel is a high risk that the grooves will break during installation or use. More waste during installation may result in the final cost per m2 of flooring being equal to or greater than the correct thickness of the panels.

Check the grooves – this is the key to a long-lasting floor.

Click-mounted SPC vinyl panels are a very broad category. Apart from the differences mentioned above, the feature that significantly influences their durability are the locking grooves. They are elements thanks to which we can connect the panels with each other. The durability of the entire floor largely depends on their quality. Poor-quality grooves may suffer numerous damages already at the assembly stage, causing very serious financial losses. SPC panels of the highest quality have a mounting system based on 5G locking grooves. Their assembly is very simple.

The 5G locking groove is the latest system patented by the Swedish company Valinge Innovation. The panels are connected in it by inserting the long side of the board into the groove profile and lowering it downwards. When two panels are properly connected, you will hear a characteristic sound, the so-called click. 2G locking grooves, which have been proven for years, are also very good. They are mounted at an angle on both the short and long sides.

The connection in this type of grooves is mechanical, the profiled elements interlock to create a permanent secure connection that protects against forces acting in all directions.

The assembly does not require any tools and the locks aren’t hit with a hammer. Most importantly, the use of such a locking groove also allows you to disassemble a fragment of the floor without the risk of damaging the grooves, which results in less waste during assembly.

A cheaper solution are locking grooves called drop downs. This type of fastening often requires “hammering” on the short side, and the panels are joined by “hammering” and stretching the milled parts of the panels. In fact, this locking groove is a one-time use, disassembly damages the panel and prevents correct re-installation. There is also no certainty of correct assembly, too light hammering may result in detachment during use, due to the natural tension of the material. Too hard impact may damage the panel during installation. There is also a risk that minor unevenness in the ground will undermine the locking groove and it will detach after installation.

Such a lock does not require such precision and accuracy in the production process, so the entire process is cheaper and the final product has a lower shelf price of up to PLN 10-20 per m2 of a comparable product with a reputable locking groove.

Beautiful SPC floor – excellent print quality

To be beautiful, vinyl panels must have a high-quality top layer. The final appearance of our home depends on how the pattern is made. High-quality prints are practically indistinguishable from, for example, natural wood. If you care about the authenticity of the pattern, avoid panels that have a digital print. Standard digital printing uses CMYK, which uses only four colours (C-cyan, M-magenta, Y-yellow, K-black). In this technique, it is difficult to reproduce the so-called wood colours – especially natural bright oak colours. It is much better in traditional printing, which uses the given colours, matched to the effect we want to achieve. Additionally, in the traditional technique it is possible to use more colours in printing.

To be beautiful, vinyl panels must have a high-quality top layer. The final appearance of our home depends on how the pattern is made. High-quality prints are practically indistinguishable from, for example, natural wood. If you care about the authenticity of the pattern, avoid panels that have a digital print. Standard digital printing uses CMYK, which uses only four colours (C-cyan, M-magenta, Y-yellow, K-black). In this technique, it is difficult to reproduce the so-called wood colours – especially natural bright oak colours. It is much better in traditional printing, which uses the given colours, matched to the effect we want to achieve. Additionally, in the traditional technique it is possible to use more colours in printing.

It is worth adding that with digital printing we deal with a much lower resolution than in the case of traditional printing (even by 50%). This also affects the overall visual effect of the entire floor. In the case of traditional printing, the material on which the pattern is applied is perfectly white foil. Thanks to this, we get almost complete colour stability. In the case of digital printing, patterns are printed on plates. Therefore, individual production batches may significantly differ in colour. So if you buy too few panels made in digital printing, it will be difficult to buy identical ones, even if according to the manufacturer it will be the same model and colour.

When choosing a SPC floor, you will certainly easily indicate poor-quality digital print. Avoid such panels, because although their price may seem more attractive, unfortunately it affects the final appearance of the room.

The last element – the finish determines the whole

The best SPC vinyl panels have a top layer and external varnish. Thanks to this structure, the print is strong and durable. The protective top layer significantly reduces the susceptibility of the panels to scratches. This is especially important in homes with small children and pets. Inferior SPC panels do not have an overprint secured with a top layer, which significantly reduces their abrasion resistance. SPC panels without this layer are not very durable and look unaesthetically after only a few months of use. There are also panels available on the market that have an additional layer of varnish, such as Titanium Nano Layer. This is an Arbiton solution that increases the scratch resistance of the panels by as much as 30%.

Check how finished and protected your SPC panels are, so that you can enjoy their flawless appearance for a long time.

Avoid it like the plague – a glued foundation

The durability of the floor is not only a panel. The entire floor system – panels and subfloor – is responsible for a long, trouble-free use. A subfloor is a very important element of a vinyl floor. Its quality determines the durability and quality of the entire floor in the room. A good vinyl subfloor creates a uniform surface that not only dampens sounds or provides better thermal conductivity. A decent subfloor also protects the floor panel against the effects of forces, absorbs shocks, falling objects and protects locking grooves.

The 2-in-1 panels with a glued subfloor appearing on the market are a product that should be especially avoided. Seemingly, this type of product is convenient. You buy a panel and an integrated subfloor at one blow. The apparent ease of assembly is also tempting. In fact, you get a medium quality vinyl panel and a very poor subfloor.

Panels with an integrated subfloor do not ensure adequate stability of the entire floor, the subfloor does not protect the most sensitive elements of the panels, i.e. locking grooves – it is usually simply not there.

The subfloor transfers the force and spreads it over a larger area. If the subfloor is glued under the panel, it does not transmit the force – all loads are therefore increased and damage to the floor is much easier.

It is worth noting that the offered subfloors integrated with the panels are usually of very poor quality foam. In addition, the thickness is often given together with the subfloor – so you buy 4.5 mm panels, in which the panel is only 3.5 mm. 2-in-1 products (panel plus subfloor) do not have good performance parameters and are not recommended by reputable sellers. Similar solutions have already been used in other types of panels, but due to numerous quality problems, manufacturers have withdrawn from this solution.

So what to choose?

Although SPC vinyl panels are a wide category in which we have a multitude of products at our disposal, every layman will easily indicate a high-quality product. Such are, for example, vinyl panels by Arbiton, Afirmax, or those available in OBI Mineral Floor stores. They are all characterized by the use of a mineral core (HD MINERAL FLOOR). This technology ensures excellent parameters, resistance, durability and high quality. These panels are offered by a leading European manufacturer, which guarantees the high quality of the final product.

To sum up, vinyl floors and panels are gaining more and more popularity mainly thanks to their features and unique properties. The multitude of solutions and technologies in which vinyl floors are made makes it worth consulting an expert before buying.

Vinyl floors are no longer just an alternative to wood or ceramic tiles. Good, rigid SPC panels will be appreciated by everyone who is looking for a combination of the beauty of wooden floors with the durability and water resistance of stoneware.