Even if you have already chosen your laminate or vinyl floor panels, you still have another choice that will define your satisfaction with your new flooring and what if you will use floor heating underlay?

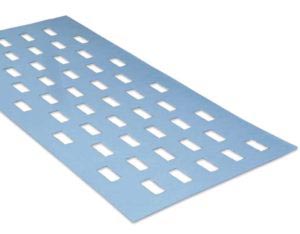

The underlay forms part of the flooring structure, and concealed under the panels it might seem to be a minor issue. This would be one huge mistake. The underlay is what protects the floor panels. Thanks to its optimum rigidity and stiffness, it protects the flooring against micro-cracks. A more down-to-earth analogy is that the underlay for your floor is like a protective case for your phone. Without an underlay, the components of our flooring that are sensitive to damage, like the joints, may quickly degrade. Manufacturers are increasingly offering underlays with perforations. Would you want a phone case with holes in it? Read on to discover just how absurd and ineffective a perforated underlay is.

Perforated underlay for heating– manufacturers doing it cheap

There are several underlay versions available, varying by perforation type, with round, square and rhomboid holes. These underlays are advertised as safe and professional solutions, and seemingly perfect for underfloor heating systems. Most of them are made from XPS (extruded polystyrene), which in itself is not a bad material. Unfortunately, an underlay with holes has one essential drawback – it cannot form a stable, continuous layer. This means it fails to protect floor panels from damage, especially the fragile joints between them.

There are several underlay versions available, varying by perforation type, with round, square and rhomboid holes. These underlays are advertised as safe and professional solutions, and seemingly perfect for underfloor heating systems. Most of them are made from XPS (extruded polystyrene), which in itself is not a bad material. Unfortunately, an underlay with holes has one essential drawback – it cannot form a stable, continuous layer. This means it fails to protect floor panels from damage, especially the fragile joints between them.

The perforated underlay manufacturers have given no sound reasons for the holes in these products. They also fail to specify the thermal resistance coefficient for these underlays, which we need in order to know how effective the underlay is for underfloor heating. The perforations in the underlay seem to be just a great way for the manufacturers to save on materials without offering any real value for the customers.

The holes formed in the underlay can lead to several unfortunate consequences.

Perforated material is uneven, causing several problems. In first place the product varies in properties across its surface. Sometimes it might be an XPS underlay with a good R coefficient, while other times it forms an insulator in the places where the holes are because the air that accumulates in them has a low density and cannot circulate freely. Air also has thermal resistance, which we need to remember in finishing and fitting out the house.

Second, sound attenuation.

Second, sound attenuation.

Laminated floor panels are loud upon impact. Adding an underlay with large penetrations creates a soundbox, amplifying every impact on the floor. If you have ever knocked on a partition wall made of hollow bricks, then you know how well the voids inside help the sound propagate better.

Third, and we are coming to the very reason we began this problem analysis. An underlay is intended to protect the floor panels. What happens when we use a perforated underlay under the panels? Those parts where the underlay has holes increases the leverage from the loads that are applied to the panels, and hence the risk of cracking the floor, especially at the joints. The instability of the material is a serious flaw of perforated underlays.

Thermal resistance, or which underlay to choose?

R factor – Thermal resistance is a concept you will want to understand before choosing the flooring for a room with underfloor heating. Thermal resistance is a measure of how good a material is at reducing heat loss. This depends on the thermal conductivity and thickness of the material.

Thermal resistance is the opposite of the heat flux volume passing through 1 m2 of the surface of a partition in 1 hour at a differential temperature of 1⁰C. Thermal resistance is designated with the symbol “R” and its unit of measure is m2K/W. The higher the thermal resistance of a material, the better the thermal insulator of the material. Conversely, the lower thermal resistance of a material is, the better the material is for flooring over underfloor heating.

For perforated underlays, the calculation of the overall thermal resistance of its material requires adding the thermal resistance of the air pockets to the standard thermal resistance range of XPS.

The overall thermal resistance depends not only on the thickness of the material, but also on the presence of ventilation. Certainly, an XPS underlay with perforations in it has a higher thermal resistance than a solid XPS layer.

The benefits of underfloor heating

The popularity of underfloor heating systems is growing because of their many advantages. First, underfloor heating provides a uniform temperature distribution across a heated room. There is no issue with colder and warmer room areas. The emission of heat from underfloor heating is pleasant and definitely favoured by anyone who hates the cold.

Underfloor heating is also great for allergy sufferers. A heated floor does not cause the air in the room to move by convection, so the movement of dust particles in the air is minimised. Underfloor heating is not favourable to the growth of mould and mildew. The drying of indoor air by underfloor heating is reduced in comparison to other space heating systems. Underfloor heating needs no radiators on the walls, giving us an unobstructed view for a better visual result. Underfloor heating does not cause the streaks of dirt which are typical of wall-mounted radiators. It should be no wonder why underfloor heating has become increasingly popular. However, if you want to install underfloor heating, you need to understand some important facts and myths.

Which underlay for heating is best?

An underlay which looks like a cut-out made during an art class is designed to increase the emission of heat, thereby improving the performance of the underfloor heating. In reality, the performance of underfloor heating first depends on the flooring solution installed. The best flooring materials for underfloor heating include tiles (vitrified or glazed) and vinyl floor panels.

If you want to go with laminated engineered wood panels, the underlay you use is critical to the underfloor heating performance. The best commercially available underlays for heated flooring are made of PUM (polyurethane mineral) materials. They provide the lowest possible thermal resistance and extreme durability (by high compressive strength, or CS), which means excellent protection of the floor panels against damage under load.

High quality, of course, means high price. A good PUM underlay like Multiprotec 1000 costs approximately 5,5 EUR/ 1 m2. Is this expensive? Not if you think logically about it. For a little over 5 EUR you get a product which guarantees your floor panels are kept in great shape for many years and cuts down the costs of space heating.

Another good solution is XPS underlay. XPS is a popular high-performance underlay material, it is up to 2 mm thick and works well with underfloor heating. However, an XPS underlay sheet must be solid to form a stable, uniform layer to stabilise the flooring. A good example is Secura Thermo Aquastop Smart.

To conclude, say no to perforated underlays. If you like cut-out patterns, get a tablecloth or a doily.